Any lopper has 2 modes; the Neutral Mode (with the trigger released and the lopper open) and the Power Mode (with the trigger engaged and the lopper cutting). ADI tools have a simplified system to open the tool in neutral mode. This system utilizes the back pressure of the hydraulic system. The principle is that in the Neutral Mode the hydraulic cylinder within the tool works as a displacement cylinder and causes the tool to open. In the Power Mode, the cylinder works as a double acting cylinder, pulling the tool closed and performing the work. As soon as the trigger is released, the cylinder automatically works as a displacement cylinder, again opening the tool. No additional parts are needed within the lopper cylinder.

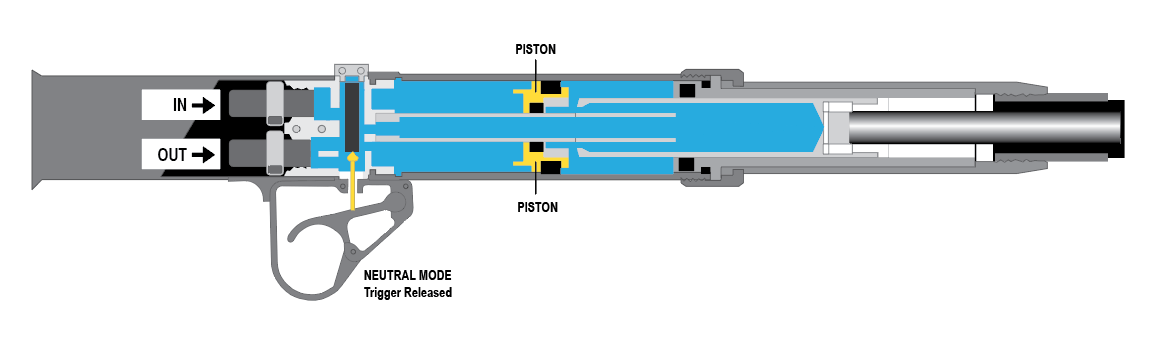

Neutral Mode - Trigger Released

As the pressurized oil enters the tool it is able to flow freely through the spool system, into both sides of the hydraulic cylinder, providing equal pressure on both sides of the cylinder piston. Because there is greater area on the handle side of the piston, greater force is created making the tool open. The drawing clearly shows that the oil flows without restriction. This makes sure that heat is not generated within the tool.

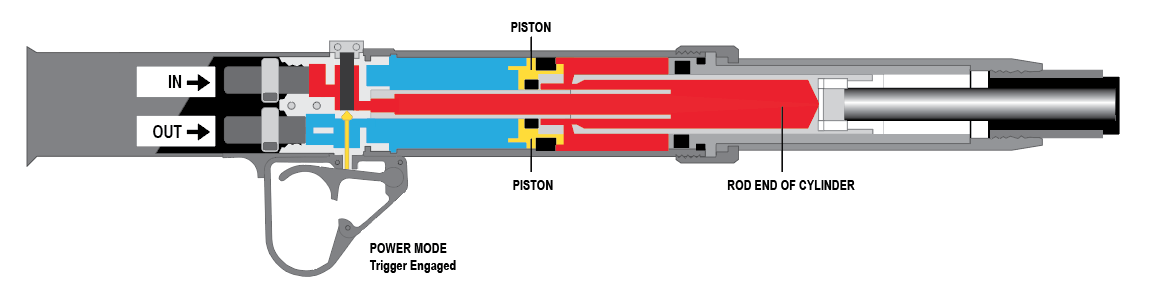

Neutral Mode - Trigger Engaged

As the trigger is pulled and the spool is shifted upward, it directs the pressurized oil into the rod side of the piston. This forces the piston downward, closing the lopper to make a cut.

Once the trigger is released, the cylinder automatically becomes a displacement cylinder, again forcing the tool to open. As always, the flow of oil is never restricted, so that heat won’t be created.

Neutral Mode - Trigger Released

Next, let’s view a lopper in the neutral mode, with the closed center plug installed. The tool still works exactly the same. The pressurized oil is stopped at the closed center plug, but it is still free to flow to both sides of the piston in the cylinder.

The cylinder is still working as a displacement cylinder so the tool will open. The difference is that high pressure (2000 psi) is being used inside the cylinder instead of low pressure. Still, the spool seals are only exposed to low pressure, reducing wear.