COOL TOOL

• OSHA Certified non-conductive lengths

• No heat generation within the tool

• Enhanced handle options

• Manual trigger lock

• Flexible hose connections

• Better weight balance

• Ease of service

SPOOL SYSTEMol

The combined advantages of ADI Hydraulic Pruning Tools make them the most rugged and reliable tools on the market. But what does that really mean? Well, it means less downtime, fewer purchased parts, and ease of servicing so that simple repairs and cleaning can be performed on site. All this equals productivity and low cost of ownership.

ADI provides a line of tools that are intended for intense daily use. Therefore, most of our customers use their tool every day for a year or more before needing any repairs. Also, the most common problem experienced after one year of daily use is a minor oil leak that can be fixed with a $1.50 O-ring.

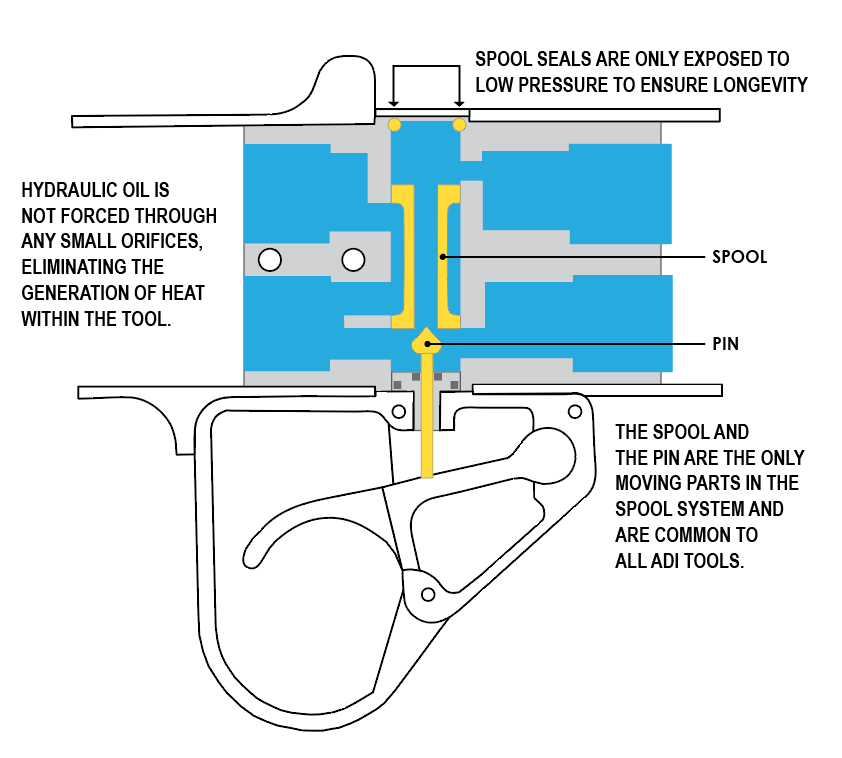

The ADI spool system utilizes a pressure-balanced spool (see drawing). This means that there is equal pressure on both sides of the spool at all times. The balancing pressure is the return pressure (low pressure) side of the tool. Therefore, the seals used in the spool system are only exposed to low pressure extending the life of the tool.

As you can see from the drawing (left), the spool system is incredibly simple and contains only TWO moving parts. Fewer parts means fewer, more simple repairs, which translates into less downtime for servicing.

Also, all the ADI tools use the same spool parts so that fewer parts need to be kept on hand.

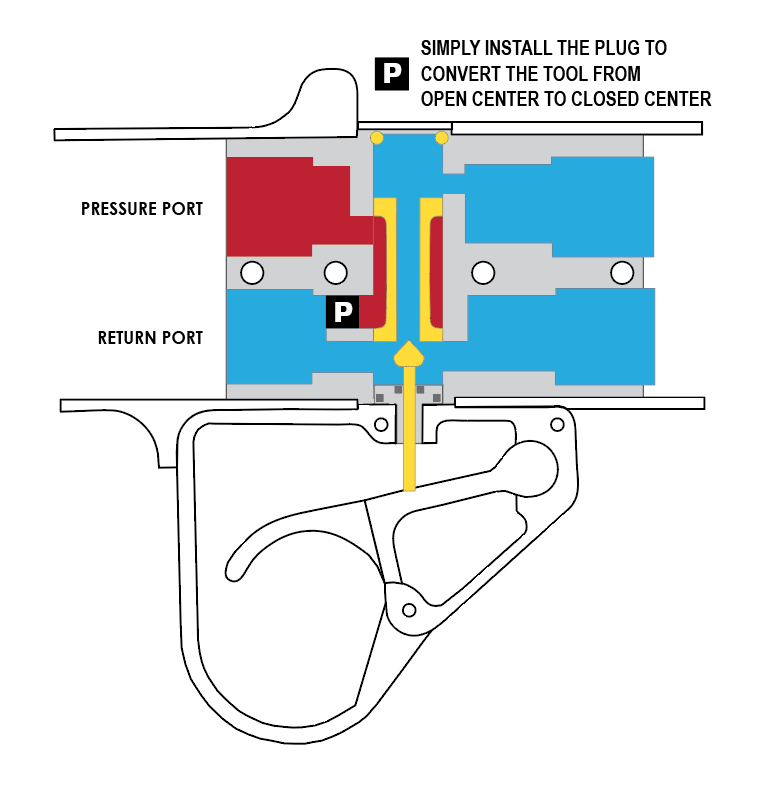

The ADI Spool System provides a fast and easy way to convert any ADI tool from open center to closed center (see below). This is accomplished by simply installing a plug in the return port in the handle of the tool. The plug is stored on the tool itself, so it will be ready whenever needed.

All the ADI tools come standard with the conversion port. There is no extra charge for the plug, nor does it increase the weight of the tools.